Wildcat Roller Screeds

Multivibe offers more choices in roller screeds than other companies, with three styles powered by Honda and one battery version. All Honda powered roller screeds will run 300 RPM max. Pick the best option for your application. Roller Tubes for the machines are made from carbon steel not aluminum. Roller screeds must have rail supports on both ends to operate and keep on grade. They are used in regular concrete and can also be used in pervious concrete. They are the easiest screed to use- even a salesman can do it.

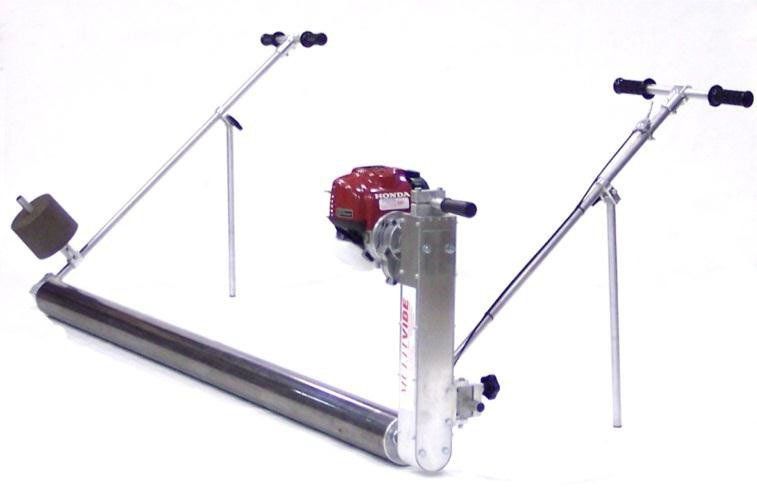

WC35

WC35 with a 35cc Honda motor. Recommended for 4.5” diameter carbon steel tube up to 16’ long.

WC50

WC50 with a 50cc Honda motor. Recommended for a 4.5” diameter carbon steel tube up to 24’long.

WC100

WC100 with a 100cc Honda motor. This option has plenty of power and will spin either a 4.5” or 6” diameter carbon steel tube up to 24’ long.

WILDCAT ROLLER TUBES

Multivibe offers two styles of roller tubes. 4.5” diameter or 6” diameter, both styles made from carbon steel which is great for concrete. Both sizes are available up to 24’ long. The 4.5” diameter size is our most popular. The 6”diameter size is a little heavier and more rigid and will move more concrete. We recommend the WC100 for a 6" Roller Tube. The End Plugs fit in the end of the roller tubes and attach to the roller screed unit. Our ends are not welded in the tubes. They are easy to install by turning one nut on the end plug. Our end plugs can be taken in and out and moved from one length tube to another.

ROLLER SCREED ACCESSORIES

Many contractors use a roller screed to place Pervious Concrete. Because our end plugs can be taken out easily, you can add water or sand inside the roller tube for extra weight if you prefer.

- For pervious applications a roller compactor is needed. Our PCR is a 60lb roller with a beveled end to eliminate lines. The weight of this tool helps close up the top of pervious and is the “bull float” for pervious concrete.

- PCRG is a roller with a flange in the center to cut joints into pervious concrete.

- CW850S is the counter weight. The counter weight can be placed on the opposite end handle to balance out the weight and to help cut concrete to grade, sometimes on the first pass.

- CPA Circular Pour attachment Replaces the opposite end handle and stabilizes pin in center of pour for applications such as grain bins.

- Sliding Height Support for all Gas-Powered Wildcat Roller Screeds.

- #OESW Opposite End Support. #DESW. Drive End Support

- Hooks to roller tube and has 6” roller wheels that let the roller tube slide down when a curb or rail is higher than grade.